Original article posted by Southwest Farm Press (Ron Smith)

Crops Manager for Daisy Farms, Jeff Fowler, is utilizing subsurface drip irrigation (SDI) and GPS technology to improve the dairy and crop operation’s efficiency. The subsurface drip irrigation system was installed on clay soils to further the farm’s commitment to conservation and environmental stewardship, as well as to get the most out of every drop of water.

The Daisy Farm operation supplies raw materials to the Daisy Brand dairy product company, and according to Fowler, “feeding a large dairy herd will take a lot of silage and forage production.” A combination of subsurface drip irrigation and GPS technology—as a means of installing drip tape accurately as well as assuring precision planting, harvesting, spray application and system monitoring—makes the job a bit easier.

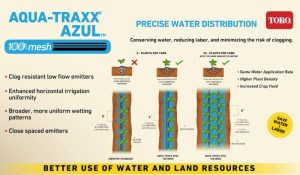

“Drip irrigation is close to 100 percent efficient,” Fowler says. “We put water straight to the roots; we get no runoff; we don’t need as much water. When we put on a half-inch, we get a half-inch. We don’t have to apply three-fourths of an inch to get what we need.”

Conserving resources is important to Daisy Farms, Fowler says. The company installed the dairy close to Paris, Texas, to serve as a model of a modern, well-run, environmentally friendly facility. Farm management takes that commitment to heart.

“We try to stretch water as far as we can,” Fowler says. “Water is not unlimited.”

He also uses the drip system to dispose of waste water from the dairy. “We run treated nutrient water through the system. The end product is clean and we have had no emitter clogging problems yet.”

“We’re basing our waste water irrigation on a comprehensive nutrient management plan, which is required by the state. We pay attention to the weather and we don’t apply nutrient water before a big rain.”

Alfalfa is the current crop of choice for drip irrigation. Eventually, Fowler will water corn and some bermudagrass with a drip system. “Alfalfa is our biggest expense, so we will grow as much as we can. Round-up ready varieties help. Along with adequate water, weed control is a big concern with alfalfa.”

He’s been watering 600 acres of alfalfa, most of that through the drip system, with 250 acres under a pivot. “The pivot was a stop-gap measure to get us started,” he says. Long-term plans call for additional acreage watered by drip irrigation. “The number keeps growing,” he says.

Dairy cow numbers and increasing feed demand will influence how many acres of drip irrigation will be necessary.

He got six cuttings last year, starting in April and cutting into October. “We kept going until a freeze hit. We’re in good shape this year going into spring. It greened up early and we had to spray for alfalfa weevil in February. We will be cutting hay in the next few weeks.” He hopes as he fine-tunes the system he’ll increase tonnage.

He’s also fine-tuning irrigation scheduling. “For now, we’re just checking the soil. We fill the profile and move onto another area. We will add moisture sensors and get on a more consistent schedule. As we get our control systems set up we will improve scheduling. We may need to add water daily as the summer heat comes on. With drip irrigation, we can put a little out consistently.”

“As we were getting the system in we had to work with getting water to the fields,” McGuire says. “Now, we’re concentrating on managing the system.”

Fowler says he used an evapotranspiration (ET) monitoring system for awhile to regulate water use but found he was putting too much water on. “We started eye-balling it and putting out what the crop seemed to need.” Moisture sensors and computer technology will make the system more efficient, he says.

To read the full article by Southwest Farm Press, click here.