Another season has passed, and Bob McKellip is happy to report that his second year of utilizing drip irrigation on mint was even better than the first. “This Spring, I started up the drip system and everything worked perfectly,” explains McKellip. “I have found that the system is very simple and easy to operate once it’s set-up, and that its just like any other piece of modern farm equipment. With drip, I easily spoon fed my crop with the water and fertilizer it needed on a weekly basis, and harvested unheard of yields on second-year mint – 188 pounds of mint oil per acre!”

Another season has passed, and Bob McKellip is happy to report that his second year of utilizing drip irrigation on mint was even better than the first. “This Spring, I started up the drip system and everything worked perfectly,” explains McKellip. “I have found that the system is very simple and easy to operate once it’s set-up, and that its just like any other piece of modern farm equipment. With drip, I easily spoon fed my crop with the water and fertilizer it needed on a weekly basis, and harvested unheard of yields on second-year mint – 188 pounds of mint oil per acre!”

McKellip noted that this was achieved in spite of record heat, minimal rainfall, and variable soils with differing water holding capacities. “With drip, I was able to fine tune the irrigation schedule to accommodate different soil types and get more water where it was needed.”

As a result, not only were yields boosted, but water and fertilizer use was down as well. “We used about half as much water and fertilizer as conventional fields – even less than planned. In addition, ground and air application expenses of $46/acre are eliminated with drip. Drip is just a really great way to apply fertilizer.”

In spite of record yields, McKellip believes they could have been even better. “Petiole samples taken prior to harvest revealed that the crop was deficient in N, P, K and S. We’ll fine tune it next year and hopefully boost yields even higher.”

McKellip explains that the water savings are just as important as the yield increase. “Some areas have a two acre foot per acre allocation, which usually forces growers to fallow some acreage. With drip, we can grow an outstanding crop with less water, leaving more water to grow more valuable crops and avoiding fallowing.”

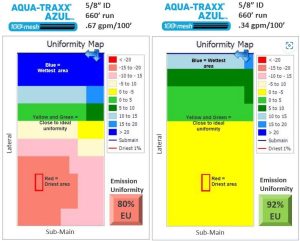

McKellip wants to amortize the drip system over multiple years, thus drip system maintenance is a priority. This spring, he replaced the end of the line f lush valves with a 3” Toro layflat flushing manifold. “Instead of manually flushing a few lines at a time, I now just open one valve and f lush 30 lines at a time. Now, I flush the system in minutes instead of hours.” A side benefit to the ease of flushing is improved system uniformity.

“Last year, there was a 2 psi pressure drop from the beginning of the 1,320’ lateral to the end. Now there is no measurable pressure loss, and the mint growth shows it – the field looks completely uniform.”

With the help of Jim Klauzer of Clearwater Supply, McKellip scheduled irrigations using four WaterMark moisture sensor stations on 38 acres. Each station consisted of three sensors: one buried 18 inches deep to monitor the moisture status beneath the buried Aqua-Traxx® drip tape lateral, and the other two straddled 15 inches away from the tape lateral and buried 8 inches deep. “Our goal was to keep the moisture status of the 18 inch sensor stable, and the 8 inch sensors moist within a specific moisture range. When the 8 inch sensors read over 20 centibars, we initiated four-hour irrigation cycles until adequate soil moisture was achieved.” The moisture data is transmitted to data-loggers positioned at the edge of the field for easy access by field staff for direct download to a computer. “We keep the irrigation schedule on a three-week calendar whiteboard that hangs in the office for everyone to see. I program the controller, but my local field staff handles everything else.”

What is unknown is whether the drip system will allow the crop to last more than the typical 5-7 years. “If I can delay the cost of reestablishment for an extra year, that will be one more very valuable benefit to add to the list.” Unsurprisingly, Bob is getting a lot of calls from his neighbors.

Click here to read the full case study update on Bob McKellip and his experiences with drip irrigation on mint. For Spanish, click here.

Here are the 2013 updated yield, and water / resource use charts and graphs: