Source: The SUGARBEET Grower

Written by Don Lilleboe

Posted April 28, 2015

Do a web search of “water use efficiency in agriculture,” and you’ll come up with a huge number of results. For Bob McKellip, the ultimate in water use efficiency on his farm boils down to two words: drip irrigation.

McKellip, who lives and works in the Treasure Valley north of Nampa, Idaho, installed his first drip irrigation — a Toro system — on one of RMF Farms’ fields in 2011. He installed a second system the following year; then, in 2013, a third. That 2013 field was seeded into sugarbeets. Prior to those drip systems, all his fields were grown under furrow irrigation.

A drip-irrigated field of mint in 2012 yielded 133 pounds of mint per acre, compared to a nearby furrow-irrigated mint field that came off at 94 pounds. The bottom line was $585 more income per acre, along with significant savings in water and fertilizer use, combined with less labor, fuel, equipment usage and insecticide inputs.

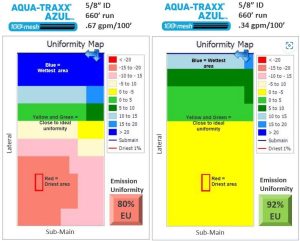

The 2013 drip-irrigated sugarbeet field’s tonnage was about equal to that year’s furrow-irrigated beets. However, the drip beets were planted three weeks later due to installation of the drip. Plus, those drip-irrigated beets produced their yield with a lot less water. “Typically, sugarbeets here will, on average, take between 45 to 55 inches of water through furrow irrigation,” McKellip says. “On the drip, we used less than 25 inches.” Also, having been land leveled many years ago, half of that field is quite gravelly, he adds. “We usually don’t grow much of a crop there with furrow irrigation because we just can’t keep the water adequate. But with drip, the sugarbeet field was perfectly uniform from corner to corner; the soil type didn’t matter. I experienced that with mint as well.”

The Canyon County producer’s standard rotation, along with sugarbeets, consists of four years in mint, followed by corn, then wheat. Unless he installs drip irrigation on another field in upcoming seasons, beets likely will not be planted again on a drip-irrigated field until 2018 or 2019.

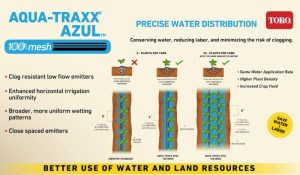

McKellip’s drip tape lines are installed at a depth of nine inches. Their expected lifespan is between eight to 10 years. Rodents — especially gophers — have an affinity for the tapes, however, so repairs are not uncommon. There’s no deep tillage in a drip field, of course. Sensors keep McKellip apprised of soil moisture conditions so that he can time irrigations appropriately. “The sensors are on a logger, set nine inches deep between the rows and 18 inches underneath the sugarbeet or other crop rows,” he explains. “We keep track of the moisture and irrigate until the moisture starts increasing on the 18-inch [sensors]. We don’t want to push the moisture too deep, because that will leach down fertilizer; there’s no reason to have it ‘super wet’ down at that depth.

“We watch the sensor at 18 inches; and as it starts to move up or down, that determines when we’re going to water. The nine-inch sensors obviously tell us when it’s time to irrigate.”

There’s certainly a significant investment of labor and time in the first year that a drip system is installed. After that, however, “there’s virtually no labor” involved, McKellip notes. “The controller is totally automatic.”

Concurrent with its water savings compared to furrow irrigation, McKellip emphasizes that there is no runoff from the drip-irrigated fields.

The crop’s complete fertility needs are fed through the tape. “We’re using about 50% less [fertilizer] on our mint, because we put it all through the system and don’t leach any out,” McKellip relates. “We’re just feeding the plant as it needs it, putting on a little at a time.” In the 2012-harvested mint, for example, he applied a total of 140 pounds of nitrate fertilizer per acre on the drip acres and 300 pounds on the furrow-irrigated mint — and the drip ended up yielding about 40% more.

About 30% less nitrogen was applied to the 2013 drip-irrigated sugarbeets, compared to that season’s furrow-irrigated beets.

McKellip’s 2013 drip beets were harvested with a Holmer self-propelled unit with its wide flotation tires. “There were no trucks in the field, as we didn’t want to damage the tape with compaction,” he says. A ROPA Maus loaded the beets onto trucks at field’s edge for transport to the factory.

McKellip says the cost of installing a drip irrigation system in his area runs between $1,200-$1,400 an acre. He benefited from a 50% cost-share program offered through the Lower Boise Watershed Council on his initial installation. Payback is estimated at 1.2 years with the cost-share, or 2.8 years without it.

“Mine is a semi-permanent system, so we’re using heavier drip tape and more-permanent fixtures,” he points out. “Components like the filters and the main line are reusable; so while we’ll need to replace the drip tape when it wears out, those other items remain intact.”

McKellip, who is president of the Idaho Mint Growers Association, believes more of the state’s mint will be grown under drip irrigation in the future — and probably more beet acres as well. Growers in his area are already quite familiar with such systems since a number of onion producers use drip. Scientists at the University of Idaho’s Parma Research & Extension Center have undertaken studies in recent years comparing drip, furrow and overhead irrigation systems and their viability for mint producers.

Article by Don Lilleboe via The SUGARBEET Grower