Original article by Nebraska Farmer (Tyler Harris)

Looking at certain parts of the Midwest from a bird’s-eye view in summer, it’s easy to see where the center-pivot irrigated fields are. Green circles dot the landscape, standing out from non-irrigated corners. But what about those corner acres?

Looking at certain parts of the Midwest from a bird’s-eye view in summer, it’s easy to see where the center-pivot irrigated fields are. Green circles dot the landscape, standing out from non-irrigated corners. But what about those corner acres?

This is something Don Blaschko and Lonnie Bohn of B&B Partners near Gibbon, Neb., considered when irrigating a 53-acre field four years ago.

The field’s elevations changes by more than 60 feet, with one border running diagonally. The field curves around two homesteads.

“We were going to try pivots, but it would take two pivots to do it,” Blaschko says. “Even with pivots, we weren’t going

to get it all watered.”

Need for Subsurface Drip Irrigation (SDI)

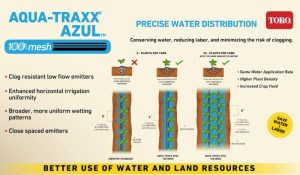

They decided to use a Toro subsurface drip irrigation, or SDI, system, which uses a network of drip tape, or tubes, 12 to 18 inches beneath the soil at varying distances apart to deliver water directly to the root system. It covers the entire field while maximizing efficiency.

“We started to look at the drip system because of the lower pressure and absolute efficiency. None of the water runs off,” Bohn says. “It’s all underground, so there is no evaporation.”

SDI was introduced more than 40 years ago in California. Sky Anderson, marketing communications manager for Toro Micro-Irrigation, says after several years of drought, more Midwest growers are using SDI, realizing the need to efficiently use water.

“SDI systems drip small amounts of water, but more continuously than pivots,” Anderson says. “With SDI, you are only using as much water as you need, so you aren’t over-watering.”

Getting the Right Fit

SDI systems are designed to fit the location. Don Masten, director of Water Resources at AgValley Co-op in Edison, Neb., designed the system for B&B.

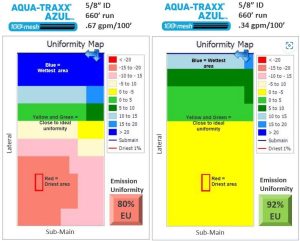

With slopes, keeping pressure uniform is critical. So, Masten used Toro’s Aqua-Traxx PC pressure compensating drip tape to keep the irrigation uniform.

He installed tape with a smaller diameter and at an angle to the hills, creating friction to counter the downhill movement of water, and making the pressure uniform.

Masten says SDI typically uses one-third the water of gravity irrigation, and just over half the water used in pivots. SDI is about 95% efficient.

By converting and using less water, Blaschko and Bohn have seen a yield increase in corn ranging from 10 to 50 bushels an acre over pivots.

“In the past, the only way to irrigate this field was a towline or hand-move system, which is very ineffective at best,” Masten says. By using SDI, B&B Partners was able to take very marginal ground and turn it into highly productive ground.”

Thinwall Dripline Available

This past winter, Toro unveiled Thinwall Dripline. Mara McCartney, Toro Micro-Irrigation product manager, says it is an option for growers who prefer to use a hard discrete emitter in a thinner-walled product. “The Thinwall Dripline is plug-resistant, making it ideal for SDI applications,” says McCartney.

The new Thinwall Dripline has a 120-mesh filtration requirement and a coefficient of variation, or CV, up to 3% to ensure emitter uniformity.

Thinwall is designed to hold up against abrasive soils to meet the needs of SDI and is available in wall thickness of 10, 13 and 15 mil.

“We use a high-grade material for our tubing. It makes installation easier and has exceptional durability,” McCartney says.

“If an SDI system is properly maintained, then it will last many, many years,” she adds.