Source: Western Grower & Shipper

Water use efficiency has long been a priority for produce growers in the United States, but with diminishing water resources there has been a renewed urgency to improve efficiency in drip irrigation systems.

Western Growers, in concert with JR Simplot Water Services and The Toro Company, recently concluded a study to evaluate distribution uniformity in drip irrigation systems in key produce regions in California, including both the Oxnard Plain and the Coachella Valley. This study was done in cooperation with Western Growers members who were interested in water efficiency and will be published soon to provide useful information to those operating drip systems.

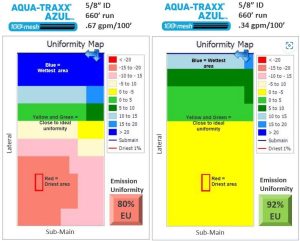

An irrigation system’s uniformity of water distribution or distribution uniformity (DU) is a key measurement of a system’s water use efficiency. If water is not distributed evenly or uniformly on a field, areas receiving less acre-feet of water may have poorer plant health and reduced crop yields. Conversely, to compensate for unequal distribution and avoid reduced yields, the system must over-irrigate.

DU, expressed as a percentage, is considered outstanding when above 90 percent, as good between 70-90 percent, and poor when it is below 70 percent. Operating with a DU above 90 percent makes good economic sense in that DU correlates closely to crop yield and reduces costs related to increased water use, which includes the water itself, energy to power the system, and often fertilizers and other chemicals run through drip systems.

These increased costs can be significant. For example, an irrigation system operating at 75 percent DU versus 85 percent DU can use more than twice the water, three times the fertilizer and increase energy cost by three times. In addition to increased costs, poor DU also impacts yield revenue. A study in 2014 (J Anshutz, “Retrofitting your irrigation system for success and profitability”) assumed an average yield of 2,500 pounds per acre and a crop value of $3 per pound. In a field with 85 percent DU, the author estimated a per-acre revenue loss of $188 due to DU degradation, while in a field with 75 percent DU, the loss grew dramatically to $563 per acre. These numbers increase substantially as DU further degrades below 70 percent, demonstrating a real impact on the bottom line for growers using poorly designed and maintained irrigation systems.

Some of the key observations during the study included the following:

- Water quality plays a key role and is critical to achieving uniform water distribution in a field. Irrigation water that comes from municipal, surface, or well sources may have very different water quality profiles. It must also be noted that water quality can change dramatically throughout the year depending on the water source or quantity available. Many substances in irrigation water can damage drip irrigation system components. Analyzing water quality prior to irrigating with a drip system will best ensure system maintenance is tailored to appropriately mitigate potential problems that may occur due to the water quality profile. Proper system maintenance to maximize DU is critical for maximizing crop yields. In fact, there is an estimated 1:1 correlation between DU and crop yield, so a 5 percent increase in DU would equate to a 5 percent increase in yield in addition to the savings of water, chemicals and energy.

- The maintenance and cleanliness of the system had a strong bearing on DU. The lack of system maintenance was observed in all the study systems. Routine maintenance and cleaning is essential to maximize performance—even when new parts are added to a system. The condition and subsequent functioning of equipment or parts quickly becomes equivalent to the old parts when they are added to a dirty system. When drip tape is not cleaned, buildup of algae, bacterial and fungal slime, biofilms, and mineral deposits rapidly reduce the water flow through the system resulting in unevenness in distribution and decreased water use efficiency. Drip tape and upstream components need to be regularly flushed with antimicrobials and/or cleaning solutions in order to maximize their performance. Due to the reduced water quality of surface water sources, especially reclaimed water, drip irrigation systems using this water have significantly more problems with reduced DU than systems sourcing from wells or municipal water providers. Use of poor quality water requires additional cleaning and maintenance efforts to maintain system performance.

- Water pressure also plays a significant part in achieving good DU. All of the systems involved in the study needed to improve pressure by installing pressure gauges and regulating valves.

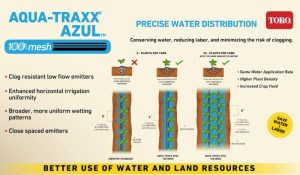

- Equipment and design also influence DU. It is important to choose parts that are appropriately designed for your drip irrigation system and the area to be irrigated. For example, not all drip tape is equal. Some systems did not use drip tape that was well-suited for the area that was to be irrigated. These systems had very long runs and would have benefited from using a different type of tape that is better suited for systems with longer runs. Some systems were especially leaking and would benefit from installation of insert tape fittings to improve connections and reduce leakage. Several of the study participants lacked flow meters on their systems or although they installed flow meters, they neglected to use them. Flow meters provide valuable information for understanding how much water is being used and how fast it is being pumped. These numbers are key factors in determining water use efficiency.

Study Recommendations

The study emphasized the importance of using proper equipment and appropriately maintaining that equipment for achieving optimal DU in drip irrigation systems. Proper use and maintenance of irrigation systems may be time-consuming, but absolutely critical for achieving maximum water distribution uniformity, an essential factor for maximizing water use efficiency and crop yield.

A summary of the study recommendations include:

- Ensure your system components are well suited for the size of the field being irrigated.

- Establish SOPs for system maintenance and schedule system inspection and cleaning on a routine basis based on water quality profile.

- Flush system with antimicrobials and/or cleaning solutions to prevent biofilm and slime formation and to dislodge any that is already established.

- Install flow meters and regularly use them to monitor water use efficiency.

- To reduce/prevent leakage, install tape fittings to improve connections.

- Install injection ports and filters at appropriate places in the system for cleaning purposes and to reduce particulate buildup.

- Install pressure gauges and regulating valves to ensure water pressure is sufficient to support a suitable DU.

Article by Hank Giclas via Western Grower & Shipper